Step into the world of enigmatic craftsmanship, where the allure of handcrafted epoxy tables beckons those with an eye for luxury and detail. Imagine a fusion of nature’s raw beauty and human artistry, meticulously melded to create a piece of furniture that transcends the ordinary. But where does such excellence originate? Look no further than the verdant expanses of Chilliwack.

Situated in the heart of British Columbia’s Fraser Valley, this gem of a location is more than just a scenic wonder—it’s the source of unparalleled wood quality that sets the foundation for these unique creations. With every grain and contour, Chilliwack’s timber tells a story of rich heritage and unrivaled purity, making it the coveted choice for these bespoke epoxy masterpieces.

Let your curiosity be piqued, and allow yourself to be drawn into the captivating journey of these distinct tables, where each piece stands as a testament to tradition, quality, and artistry.

Understanding Epoxy Tables

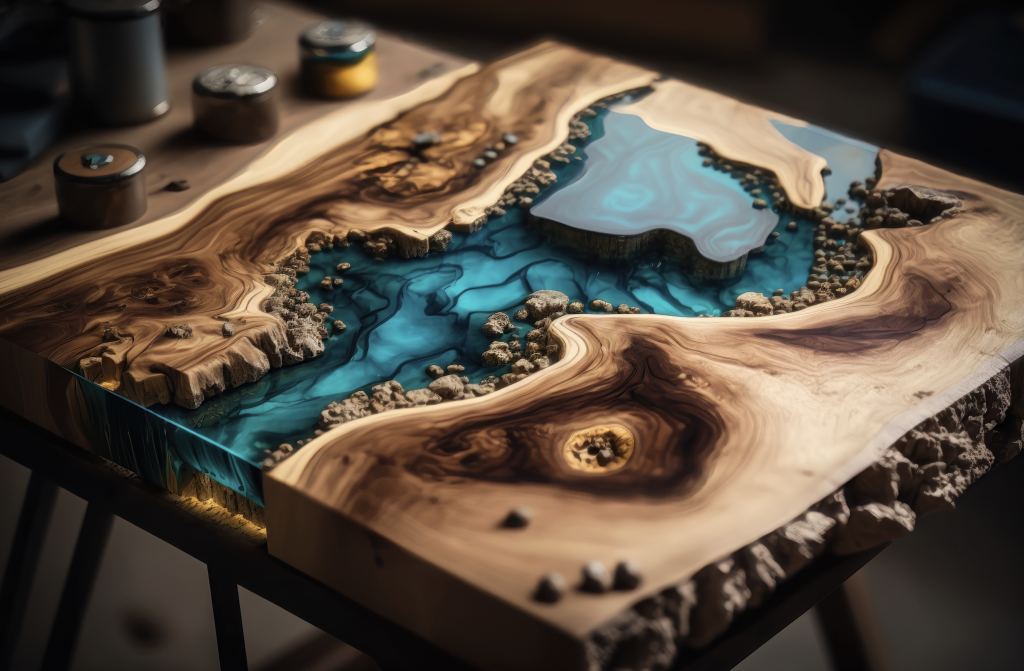

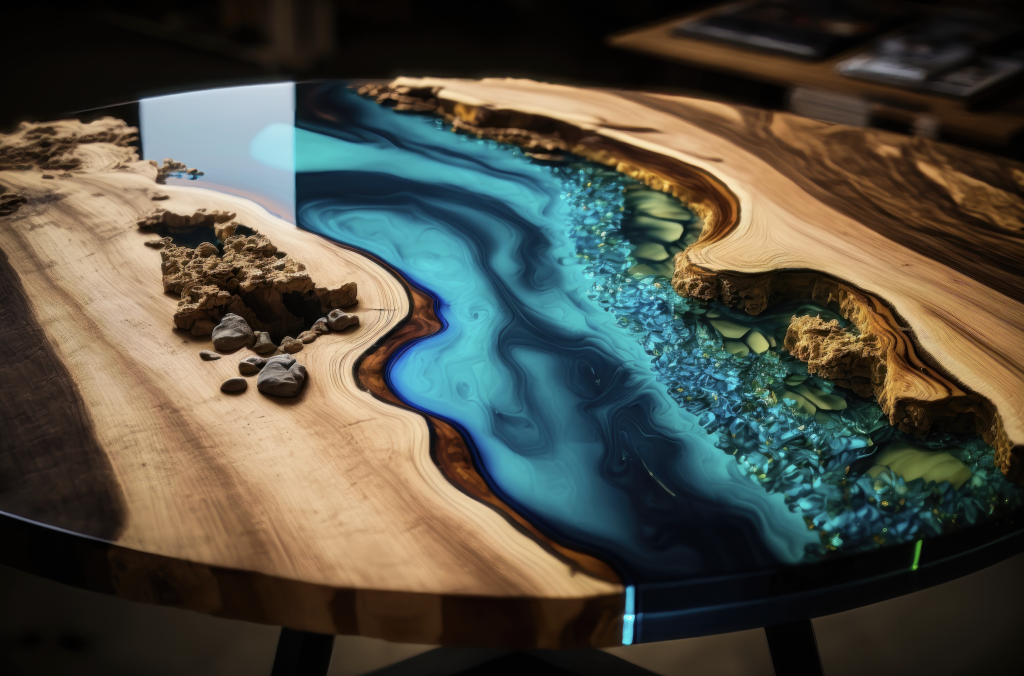

Where timeless craft meets contemporary flair, epoxy tables come to life. They aren’t just furniture; they merge resin with wood, weaving in tales, artistic impressions, and nature’s touch. Epoxy resin, a fluid that solidifies over time, is poured onto wood segments, giving birth to distinct designs or beautifully encapsulating items, leaving a lustrous, enduring surface.

The Allure of Live Edge Wood

So, what sets live edge wood slabs apart from epoxy tables? Simply put, ‘live edge‘ refers to woodcuts that retain the tree’s original contours rather than being uniformly trimmed. Every slab becomes a testament to the tree it once was, offering a unique design and story.

Why Live Edge is the Top Choice for Epoxy Tables

Here’s the magic behind incorporating live edge slabs into epoxy tables:

- Captivating Natural Look: The raw edge, with its irregularities, contrasts perfectly with the polished epoxy, crafting a harmonious balance between rustic allure and chic elegance.

- Distinct Patterns: The inherent grain, knots, and nuances in every slab mean each epoxy table stands out, boasting its own identity.

- Upscale Custom Feel: The combination of translucent epoxy and the tactile feel of live edge slabs crafts a sumptuous end product, making it both an art piece and a functional item.

- Variety of Wood Choices: From the deep richness of walnut and the warm tones of cherry to the intricate grain of maple and the sturdy elegance of oak, each hardwood lends its own unique character to the live edge epoxy table, allowing artisans and homeowners to select the perfect canvas for their bespoke creations.

Fraser Valley: A Wood Lover’s Paradise

So where do you find the best live edge wood slabs? Look no further than Chilliwack’s Fraser Valley in British Columbia Canada. This verdant sanctuary in Western North America is abundant with trees, leading to a rich assortment of wood and unmatched quality. It’s mild climate and nutrient-rich soil nurture a plethora of tree varieties, offering craftsmen a broad spectrum of choices.

Chilliwack Epoxy Tables: The Perfect Synthesis of Skill and Material

For those in search of the ideal blend of top-notch craftsmanship and superior materials, Chilliwack Epoxy Tables stands out. This local gem taps directly into Fraser Valley’s woodland treasures. Passionate artisans, deeply attuned to their environment, channel the area’s intrinsic splendor into each table, crafting not just furniture, but a narrative and a heritage.

CREATING Live Edge Wood Slab Epoxy Tables

Creating live edge wood slab epoxy tables is both an art and a science. This intricate process ensures that each table is unique and embodies both the natural beauty of the wood and the design aesthetics of the epoxy resin.

Here is a detailed step-by-step process of how such tables are hand-made:

Selecting the Wood Slab: The process begins with selecting the right wood slab. Hardwoods such as walnut, cherry, and maple are popular choices due to their durability and beautiful grain patterns. The “live edge” refers to the natural edge of the wood, which retains the contours of the tree.

Preparing the Wood: Once a slab is chosen, it’s dried properly—either air-dried or kiln-dried—to reduce the moisture content and prevent warping or cracking in the future.

Design and Layout: The craftsman decides on the design. This involves determining where the epoxy will go and if any additional elements, such as stones or shells, will be incorporated into the design.

Cleaning and Leveling: The slab is cleaned of any dirt or debris, and any holes, knots, or imperfections that need to be filled with epoxy are identified. The slab might be planed or sanded to ensure it’s flat and level.

Setting Up a Mold: A mold or frame is set up around the wood to contain the epoxy resin when poured. This is usually made from materials like melamine or silicone, which epoxy doesn’t stick to.

Mixing and Coloring the Epoxy: Epoxy resin and hardener are mixed in the correct ratio. Pigments or dyes can be added at this stage to give the epoxy a desired color or effect.

Pouring the Epoxy: The mixed epoxy is poured slowly and carefully to avoid bubbles. Depending on the design and depth of the pour, multiple layers may be needed. Each layer might need to cure before the next is added.

Curing: Epoxy resin needs to cure for a specific period, which can vary based on the product used. It’s important to ensure that the curing environment is dust-free and at the recommended temperature.

Demolding and Sanding: Once fully cured, the slab is removed from the mold. The table is then sanded, starting with a rough grit and working up to finer grits for a smooth finish.

Finishing: A final finish, such as a clear polyurethane or oil, is applied to protect the wood and epoxy and enhance their beauty.

Attaching the Legs: Depending on the design, custom legs or bases are attached to the slab.

Quality Inspection: Before delivering to discerning clients, the table undergoes a thorough inspection to ensure there are no defects and that it meets the highest quality standards.

End Product Quality: The finished product is a fusion of nature and craftsmanship. The live edge maintains the organic, raw feel of the wood, while the epoxy can add a modern, artistic touch. When done with precision and care, these tables become durable, functional pieces of art that can serve as conversation starters and centerpieces in any living or working space. The amalgamation of wood and epoxy ensures longevity, given that both materials are sealed and protected.

With proper care, these tables can be cherished for generations.